The auto clam-shell helium leak test system for automobile parts is designed to find vulnerabilities in auto parts. Products are tested under atmospheric conditions. The machine is relatively simple and affordable to operate.

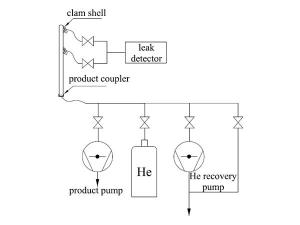

Test Concept

Evacuate the product and charge helium into the product.

Evacuate the clam shell.

Test the helium signal from the clam shell by the leak detector for fine leak detection.

Recover helium from the product.

Technical Parameters

Cycle time: 1min./pcs.

Leak rate: 1×10-3mbar.l/s - 1×10-5mbar.l/s

Test pressure: 2-42bar

Main Parts of System

Vacuum pump: Leybold

Vacuum sensor: Inficon

Helium leak detector: Inficon

Pressure sensor: GE

Solenoid valve: Burkert

PLC: Omron

HMI: Omron